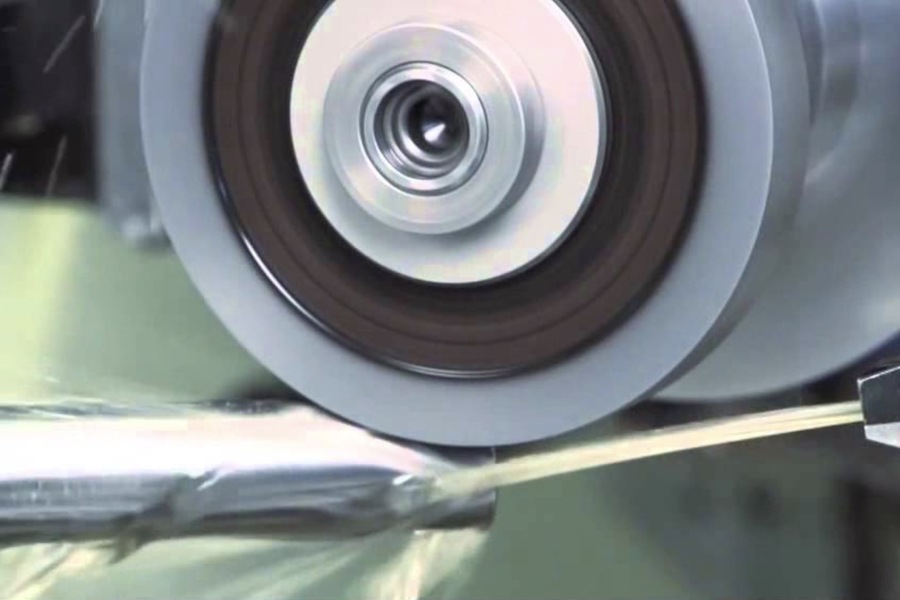

In the heart of every industrial revolution, there lies an unsung hero—a tool or innovation that quietly but powerfully transforms the way we work. For today’s industrial sector, the Tyrolit grinding disc is precisely that hero. With its cutting-edge engineering, unparalleled durability, and precision, this tool is revolutionizing industries ranging from construction to manufacturing.

Let’s delve deeper into why Tyrolit grinding discs are regarded as the “arms” of the industrial sector, providing both strength and finesse in equal measure.

Page Content

The Backbone of Industrial Precision

Grinding discs are essential in shaping, smoothing, and cutting materials like metal, concrete, and stone. The Tyrolit grinding disc takes this utility to a new level, offering a unique combination of precision and power. Founded on the principles of advanced engineering, Tyrolit has carved a niche in producing high-quality abrasives, with its grinding discs leading the charge.

But what sets these discs apart? The answer lies in the trifecta of innovation, efficiency, and reliability.

- Innovation in Abrasives

Tyrolit grinding discs are manufactured using state-of-the-art technology that integrates high-performance abrasives with durable bonding agents. This innovation ensures:

Longevity: Tyrolit discs last significantly longer than conventional grinding discs, reducing replacement costs.

Versatility: From smoothing welds to cutting through thick slabs of concrete, these discs are designed for multi-purpose industrial use.

- Efficiency Redefined

According to a report by MarketsandMarkets, the global abrasives market is projected to reach $57 billion by 2027, with demand fueled by industries prioritizing precision and efficiency. Tyrolit’s grinding discs contribute significantly to this growth by reducing operation times and improving output quality.

- Reliability Under Pressure

In industries where time is money, reliability is critical. Tyrolit grinding discs are rigorously tested under extreme conditions to ensure they withstand high rotational speeds and intense friction, making them a trusted choice across the globe.

Applications Across Industries

The versatility of the Tyrolit grinding disc makes it an indispensable tool in various industrial sectors. Here’s how it arms these industries with unparalleled capability:

- Manufacturing

In manufacturing, precision is non-negotiable. Whether it’s refining metal surfaces or preparing components for assembly, Tyrolit grinding discs deliver exceptional results. Their ability to handle delicate operations without compromising strength is particularly valued in automotive and aerospace industries.

- Construction

Construction sites are a playground for Tyrolit grinding discs. Their robustness and efficiency are vital in cutting, grinding, and smoothing materials like stone, concrete, and tiles. This is particularly critical in high-pressure scenarios where delays can lead to significant financial losses.

- Shipbuilding and Heavy Machinery

Heavy industries like shipbuilding require tools that can endure rigorous workloads. Tyrolit grinding discs excel in grinding and polishing large metal components, ensuring durability and safety in finished products.

- Renewable Energy

With the renewable energy sector growing at a CAGR of 8.4% (IEA, 2023), Tyrolit grinding discs are finding applications in fabricating wind turbine components and solar panel structures, where precision and strength are paramount.

Economic Impact and Cost Efficiency

Reduced Downtime

A significant advantage of Tyrolit grinding discs is their ability to reduce operational downtime. Their extended lifespan means fewer disc changes, allowing uninterrupted workflows and higher productivity.

Energy Savings

Thanks to their optimized design, Tyrolit grinding discs require less energy for operations compared to conventional alternatives. This contributes to cost savings and aligns with sustainability goals—a growing priority for industries worldwide.

Lower Maintenance Costs

The precision and durability of Tyrolit grinding discs mean reduced wear and tear on machinery. This translates to lower maintenance costs and a longer lifespan for industrial equipment.

A Technological Marvel: The Engineering Behind Tyrolit

Tyrolit grinding discs are more than just tools; they’re technological marvels. Here’s a glimpse into the features that make them stand out:

High-Tech Bonding Agents: These agents enhance the abrasive grains’ adherence, ensuring consistent performance even under high temperatures.

Ergonomic Design: Lightweight and easy to handle, Tyrolit grinding discs reduce operator fatigue, improving overall productivity.

Eco-Friendly Manufacturing: Tyrolit is committed to sustainability, employing environmentally friendly production processes that minimize waste and emissions.

Challenges in the Industry

Despite their benefits, challenges exist in adopting Tyrolit grinding discs widely:

Initial Investment: High-quality tools like Tyrolit grinding discs often come with a premium price tag, which may deter smaller businesses.

Skill Requirements: Effective use requires skilled operators familiar with industrial-grade equipment.

Market Competition: The abrasives market is saturated with low-cost alternatives, making it essential to educate businesses on the long-term benefits of investing in Tyrolit products.

Why Tyrolit is the Future

The demand for precision tools like Tyrolit grinding discs is only set to grow as industries become more quality-focused. Innovations in automation and smart manufacturing will likely integrate Tyrolit’s advanced features, cementing its place as a cornerstone of industrial operations.

By combining cutting-edge technology, unmatched reliability, and a commitment to sustainability, Tyrolit grinding discs are not just tools—they’re the arms empowering the industrial sector to achieve its highest potential.

Final Thoughts

The industrial world often celebrates grand machinery and towering structures, overlooking the humble tools that make it all possible. The Tyrolit grinding disc is a testament to the power of precision and innovation, proving that even the smallest tools can drive monumental change. As industries strive for efficiency and sustainability, embracing Tyrolit grinding discs is more than a choice; it’s a necessity. Whether it’s shaping steel for skyscrapers or smoothing metal for aircraft, these discs truly are the arms holding the industrial sector together.

Baseball fan, coffee addict, audiophile, hand letterer and front-end designer. Performing at the crossroads of design and sustainability to develop visual solutions that inform and persuade. My opinions belong to nobody but myself.